What is a treadmill motor?

A treadmill motor is the engine that powers the treadmill belt, allowing it to move at various speeds of the treadmill. It’s a crucial component of any treadmill motor with some key points.

The motor’s power is usually measured in horsepower (HP) or continuous duty horsepower (CH). These are units of measurement. Treadmill motors typically range from 1.5 to 4.0 CH for home use, not commercial use.

Typical power ratings for home treadmills:

For entry-level 1.5 – 2.5, CHP power ratings for home treadmills are in the motor range.

The motor range is the mid-range 2.5 – 3.5 CHP power rating for home treadmills.

For High-end 3.5 – 4.0+ CHP power ratings for home treadmills is the motor range.

Commercial treadmills:

Commercial treadmills often have higher ratings, sometimes exceeding 5.0 CHP, and are mainly used in gyms.

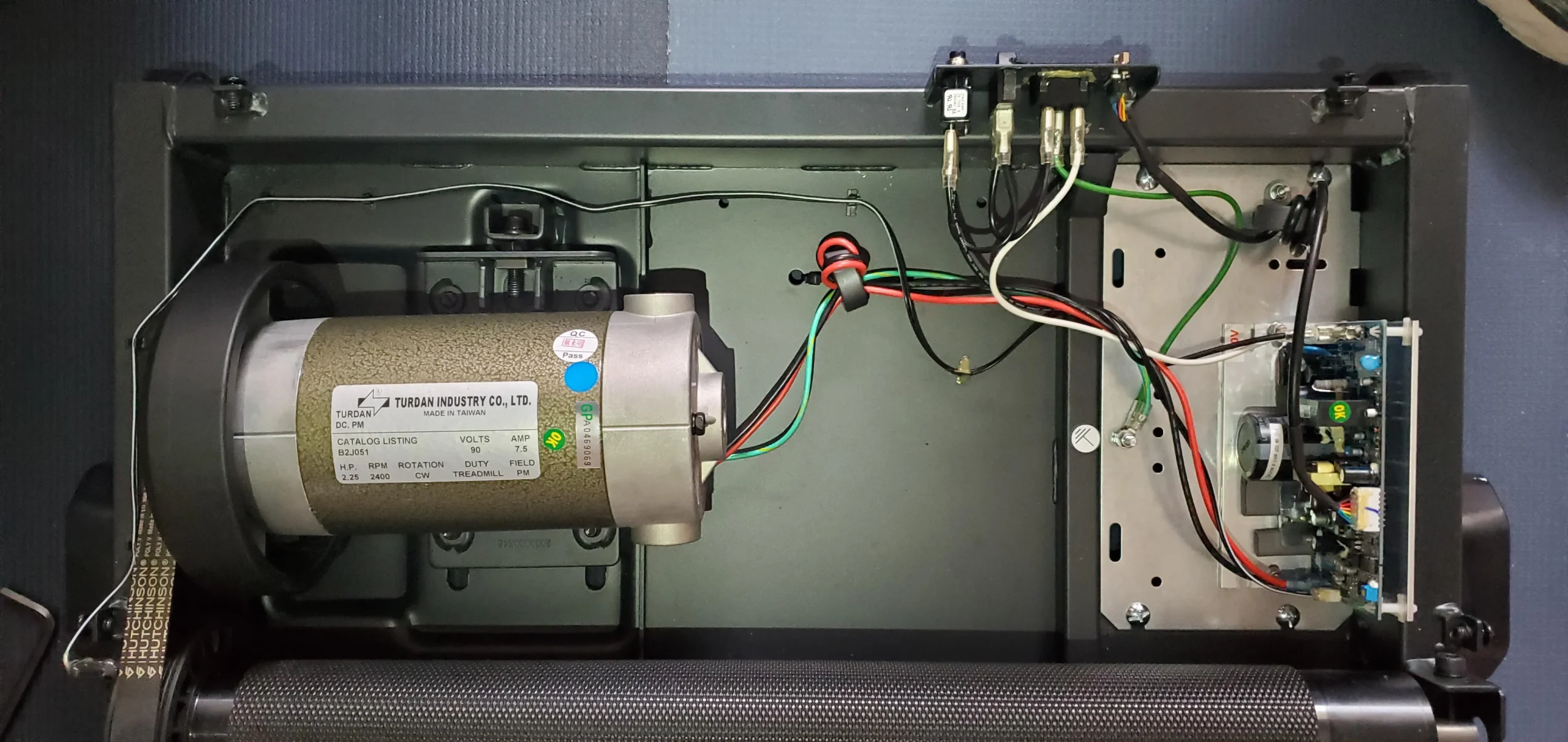

- Armature: The rotating part of the motor and the belt.

- Field magnets: Create the motor’s magnetic field.

Commutator: Reverses current direction to keep the armature spinning or immature of the rotating part. - Brushes: Conduct electricity to the commutator for the rotating motor pavilion.

What is the function of the treadmill motors?

The function of the treadmill motor is to drive the belt on which you walk or control the belt’s movement and performance.

What are the types of treadmill motors?

There are two types of treadmill motors: DC (Direct Current) Motors and AC (Alternating Current) Motors.

DC (Direct Current) Motors: Most common in home treadmills, quieter and more energy-efficient for homes and offices.

AC (Alternating Current) Motors: These are often found in commercial treadmills, but they are more powerful and durable for gym treadmills or other large treadmills.

What are the power ratings of treadmill motors?

Motor power rating is measured in horsepower (HP), a unit that also ranges in home uses, typically from 1.5 HP to 4.0 HP.

What are the key specifications of treadmill motors?

Key Specifications of treadmill motor are Continuous Duty Horsepower (CHP)and Peak Horsepower:

What are the components of a treadmill motor?

The Components of the treadmill motor are a flywheel and a cooling fan.

Flywheel: It helps maintain the consistent speed of the treadmill.

Cooling fan: Prevents overheating during operation or workout on the treadmill.

What are the Quality Factors of treadmill motors?

Quality Factors of the treadmill motor are RPM (Revolutions Per Minute and Torque.

RPM (Revolutions Per Minute): Higher RPM generally means smoother operation and improves quality.

Torque: Affects the motor’s ability to handle heavier loads of the treadmill.

What is the maintenance of the treadmill motors?

Maintenance of treadmill motor lubrication and cleaning and the overall lifespan of the treadmill. Your needs and ensuring proper maintenance Understanding the treadmill motor is crucial for choosing the suitable machine.

EXPLAIN COMPONENT OF THE TREADMILL:

A typical treadmill motor has two main components

Motor type: Most treadmill motors are DC (Direct Current) motors. Specifically, they are often permanent magnet DC motors.

What are the quality factors of the treadmill motor?

The quality factors of a treadmill power motor are crucial and challenging to understand when determining its performance, durability, and overall user experience.

-

Efficiency

Higher-efficiency motors convert more electrical energy into mechanical energy, effectively reducing power consumption and heat generation while increasing the treadmill’s quality. -

Durability

Quality motors use better materials and construction techniques to withstand prolonged use and stress for the user. -

Heat Dissipation

Better heat management prevents overheating and extends motor life. Because it is a quality factor, the motor is used. -

Quiet Performance

Lower noise levels indicate better design and construction, providing a quieter workout experience. No noise level creates no stress during workouts. -

Torque Consistency

Maintaining consistent torque throughout the speed range ensures smooth operation and maintains the user’s consistency. -

Fast Response

Quick acceleration and deceleration improve user control and safety and increase the response time for low voltage. -

Brushless Design

In DC motors, brushless designs tend to be more efficient and durable, and the design of the motor is attractive. -

Premium Magnets

Higher-quality magnets in the motor improve performance and efficiency. -

Superior Bearings

Reduces friction and noise, improving motor longevity. -

High-Class Insulation

Better insulation allows the motor to withstand higher temperatures and low power consumption. -

Vibration Level

Lower vibration indicates better balance and motor construction quality during a workout.

Key components:

How do you choose the right motor power for specific needs, or how do these ratings affect treadmill performance?

Choosing the right motor power for specific needs and ratings affects treadmill motor parts performance.

Power Rating:

- Continuous Duty Horsepower (CHP) in-house treadmill uses

Peak Horsepower (PHP) is used for commercial treadmill power ratings. -

Voltage:

Typically, 120V or 240V for home treadmills are used for workouts.

Some commercial models may use higher voltages due to heavy motors. -

Current Draw:

Measured in amperes (A), it is used in the home or commercial treadmill. -

Speed Range:

Usually measured in miles per hour (mph) or kilometers per hour (km/h) uses both home and commercial uses.

Typical range: 0.5 to 12 mph for home treadmills in the treadmill’s speed. -

Torque:

Measured in Newton-meters (Nm) and Indicates the motor’s ability to overcome resistance -

RPM (Revolutions Per Minute):

Indicates how fast the motor spins per revolution per minute, which is used for speed. -

Noise Level:

The noise level for this unit was measured in decibels (dB). -

Duty Cycle:

The percentage of time the motor can operate continuously without overheating is measured in the duty cycle. -

Cooling System:

Cooling (e.g., fan-cooled) is used in the motor to overcome the heating. -

Motor Type:

Usually DC (Direct Current) and AC (Alternating Current. -

Drive System:

A belt drive or direct drive system is used in the treadmill. -

Efficiency Rating:

Indicates how effectively the motor converts electrical energy to mechanical energy, an efficiency rating.

Maintenance of a treadmill motor is crucial for ensuring longevity and optimal performance. Here are key aspects of treadmill motor maintenance

-

Regular Cleaning:

Remove dust and debris from the motor compartment using compressed air or a vacuum cleaner with a brush attachment. -

Lubrication:

Lubricate moving parts as per the manufacturer’s instructions

Avoid over-lubrication, which can attract dust -

Belt Tension:

Check and adjust the running belt tension regularly, reducing strain on the motor. -

Alignment:

It should ensure the belt is properly aligned to prevent uneven wear on the motor or any hazard. -

Electrical Connections:

Inspect and tighten any loose electrical connections, and beware of any signs of wear or damage to the wires. -

Cooling System:

When the fan is working correctly, Ensure the motor’s cooling and Keep vents clear of obstructions. -

Usage:

Avoid overloading the motor beyond its rated capacity and Allow cool-down periods between intense workouts on the treadmill. -

Power Supply:

Use a surge protector to prevent electrical damage and Ensure a stable power supply. -

Regular Inspections:

Listen for unusual noises during operation, which could indicate overheating, and Check for any burning smell -

Professional Service:

Have a technician Schedule periodic professional maintenance and check internal components annually -

Brush Replacement:

When worn, replace them with brushes for DC motors. -

Software Updates:

If applicable, keep the treadmill’s software up to date with a specific time of the treadmill motor.

-